Omega Series

- Home

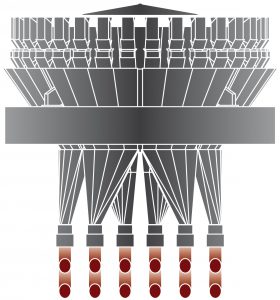

- Multihead Weigher

- Omega Series

Dataweigh OMEGA

At the pinnacle of technology

Environmental responsibility

- Yamato Feedback | Control for high speed weighing with 60% less power consumption compared to previous model

- Large product window for perfect sealing contributes to the reduction of packaging waste during production

Improved productivity

- Technological innovation for higher speed and precision

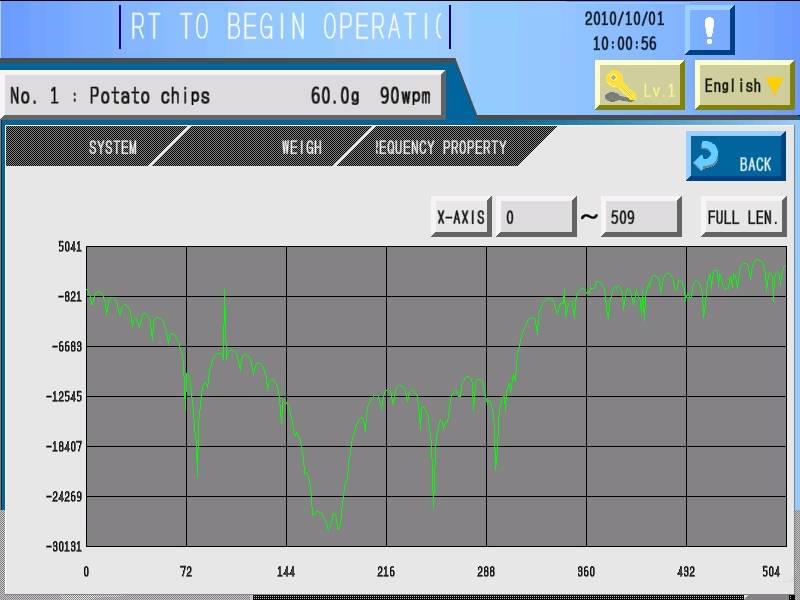

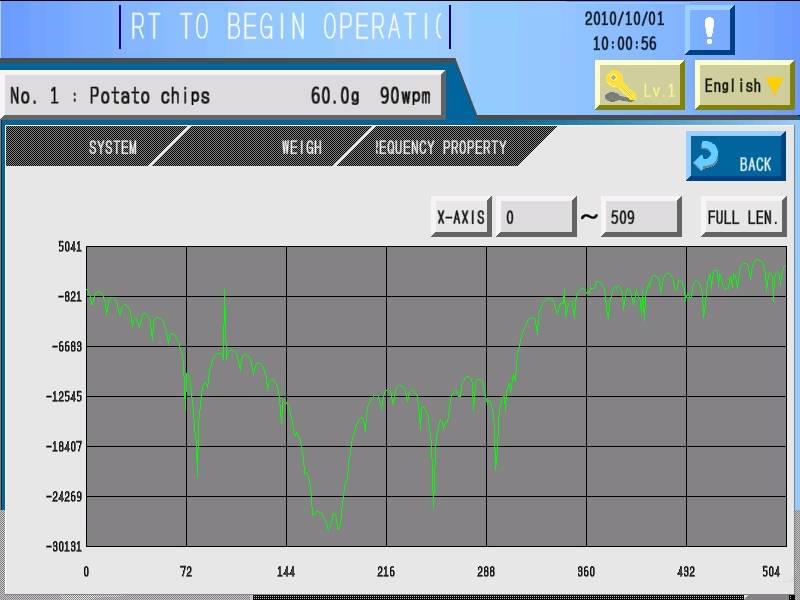

- New high frequence technology minimizes load cell vibrations

- New digital filter for maximum speed

- New toggle-less gating mechanism reduces the mechanical impact on the load cell and suppresses the bucket gating noise

- New individually adjustable collating chutes for high speed discharge, utmost flexibility and enhanced product diversity

- High accuracy reduces product waste, thereby improving the yield rate and reducing the power consumption

- Yamato Auto | Tuning and Yamato’s Automatic Feeding Control (AFC) ensure a continuous and optimal product flow

Easy maintenance

- Innovative maintenance concept to reduce the time and costs required for maintenance, thereby minimizing downtime

- All parts are easy to remove

- Extensive warning systems in case of error

- Monitoring of the wear of consumable parts indicating point at which they need to be replaced

Enhanced hygienic features

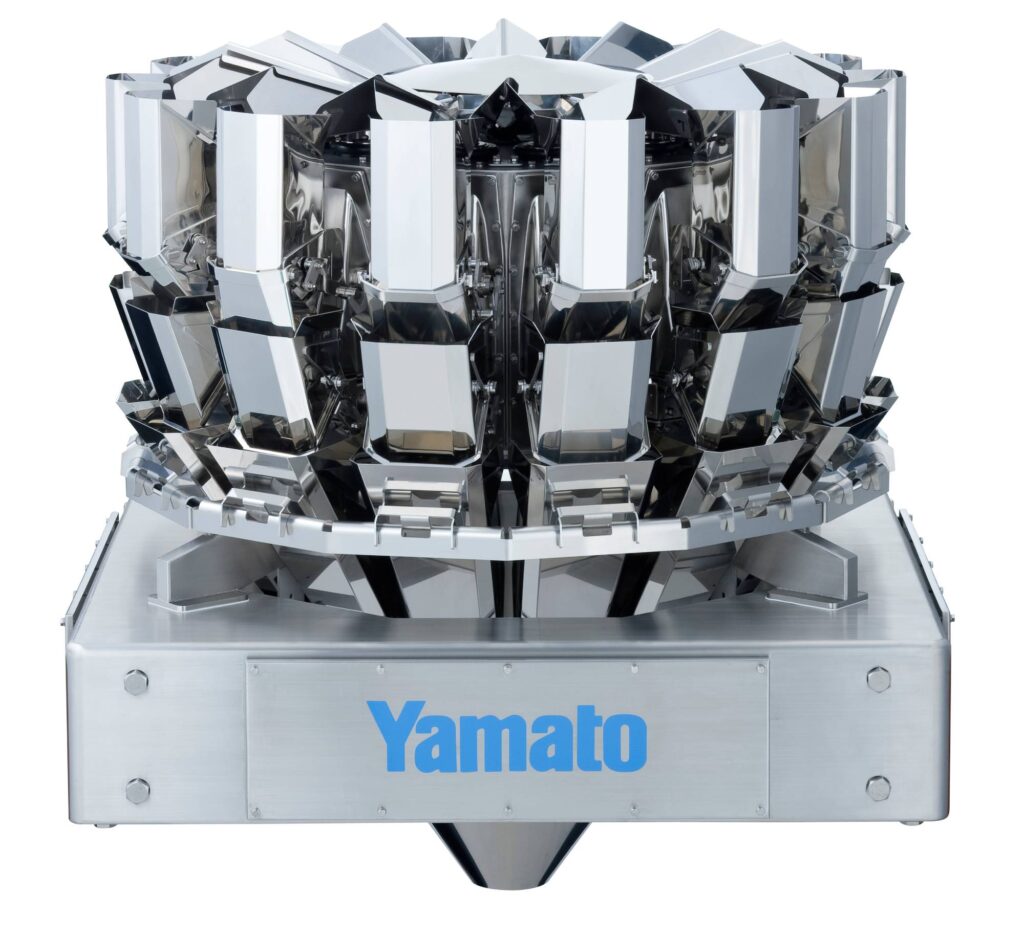

- Polygon bucket shape facilitates cleaning

- Complete stainless steel design (Ip67) allows for the highest hygiene standards to be met

- Special bonding techniques specific to space and aviation technology provide state-of-the-art materials for the buckets

Easy operation

- New 12,1” color touch screen monitor

- The world’s first Auto Tuning function for a quick and easy set-up

- New self-explanatory user interface

Yamato Multihead Scale OMEGA

Applications

Dataweigh OMEGA Frontier

Improve your productivity!

The idea: “To maximise packaging machine capability”

The solution: Yamato Omega Frontier

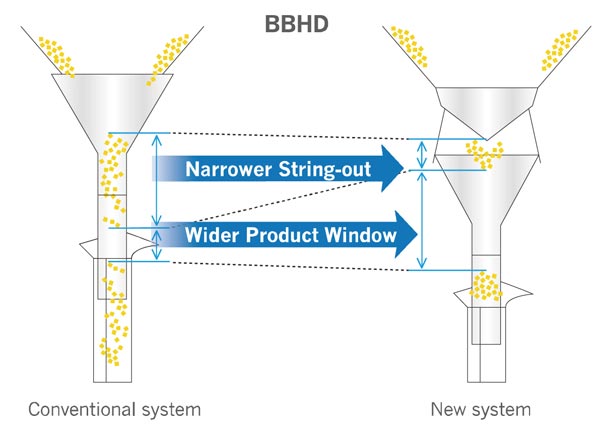

The output of Multihead weighers in existing production lines has been increased by using advanced weighing technologies like single, double and triple shift operation. The problem within these developments is that the product window (to seal products in the packaging machine) is smaller and this causes sealing failures in the package.

Only the Yamato Omega Frontier Multihead Weighers with the unique technology solve these problems and increase the output of packaging machines:

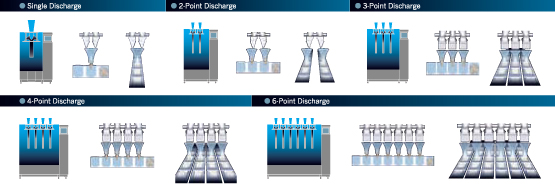

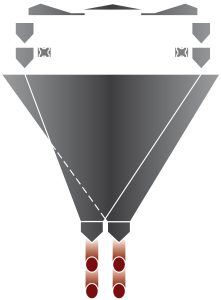

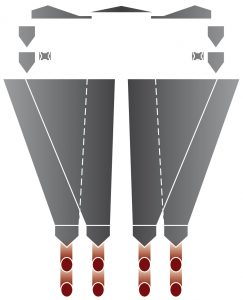

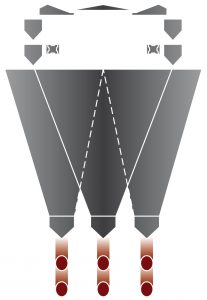

Multipoint Discharge

From 1 up to 6 Discharge Gates Yamato Multihead weigher can fill tray lines, cup lines, HFFS, VFFS, rotary packing machines and other similar packaging applications. Multipoint Discharge allows increase of production.

Simultaneous Combination

Realized high accuracy and output. Less give away for a fast return-on-investment.

Case examples of advantages of the Omega Frontier concept:

Confectionery Products:

For example, ADW‐O‐0114F enables a high speed 200 bags per minute into single tube with 2‐way by candies by 50 g target weight. The ADW is also perfect for a Duplex Packaging Machine using the simultaneous 2 point discharge.

The ADW-O-0128F runs with a speed of 320 bags per minute for candies with a target weight of 100g into a 4 tube line cup filler.

The ADW‐O‐0620F

With a target weight of 500g of vegetables, ADW‐O‐0620F enables high speed weighing at 180 bags per minute (3 x 60 bpm) with a 3-point simultaneous discharge.

High Speed weighing:

The ADW-O-0132F enables really high speed weighing, 600 weighments per minute with a 6 point simultaneous discharge.

Of course there are more applications available, like snacks, fresh and frozen, dry and pet food products.

The Yamato Omega Frontier Concept expands further future of weighing packaging systems:

- Reducing number of production lines

- Reducing production costs (less operators)

- Saving operation space by smaller machines

- Less waste by increasing the product window

- Less film costs by gentle speed and high output

- Better ROI by extended machine life